Infrastructure Facilities

HEMRL is the only laboratory in India where research and development work in the entire range of high energy materials viz. gun and rocket propellants, high explosives, pyrotechnics etc. is conducted. In addition to a number of laboratory analytical instruments, facilities are available at this laboratory for study of explosive, propellant and pyrotechnic phenomena. Some of the facilities are:

- Measurement of flame intensity in visible & IR regions

- Measurement of Flame temperature

- Synthesizing high energy materials

- Instrumental facilities for characterization of energetic materials

- UV-Visible Spectrophotometer

- FTIR Spectrophotometer, TG-FTIR

- Simultaneous Thermogravimetric Analyser (STA)

- High Performance Liquid Chromatography

- Gel Permeation Chromatography (GPC)

- Pyrolyzer GC-MS

- Vapour Pressure Osmometer (VPO)

- IC, NMR, SEM

- Pilot plant for high energy materials & allied chemicals

- Rocket testing in static conditions

- Study of detonation phenomenon

- Determination of mechanical properties of propellants & polymers

- Testing & Evaluation of Solid Rocket Propellants

- Specialized infrastructure for Processing and evaluation of rocket Propellants

- Electronic and Optical Instrumentation Systems

- Non Destructive evaluation facilities

- Mechanical properties evaluation facility by using UTM

- Safety Engineering related facilities

- Technical Information Resource Centre

- 10G based Computer Network

Photographs of some of the available facilities are given below

Computed Radiography (CR) System

Universal Testing Machine (UTM)

450 kV X-ray Machine with Flat Panel Detector (FPD)

450 kV mini focus X-ray Machine with Flat Panel Detector (FPD)

4-MeV Linac X-Ray Radiography Facility

Ultrasonic NDE Facilities

6-MeV Linear Accelerator (LINAC) System

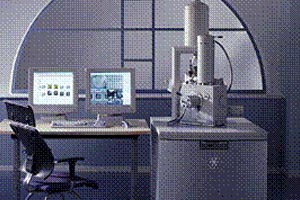

Raman Spectrometer & Scanning Electron Microscope

Strand Burner Equipment

Rocket Propellant Testing Facilities

Gun Propellant Testing Facilities

IR Intensity Measurement

Underwater Blast Measurement

Bomb Calorimeter (Julius Peter)

Gas Chromatograph (GC)

Gas Chromatograph Pyrolyser

Ion Chromatograph (IC)

Accelerated Solvent Extractor (ASE-200)

Atomic Absorption Spectrophotometer

UV-VIS-NIR Spectrophotometer

Abels Heat Test Bath

Vapor Pressure Osmometer (VPO)

Bergmann and Junk Test Bath

Vacuum stability Test Bath

BAM friction Test Apparatus

BAM Fall Hammer Test Apparatus

High Performance Liquid Chromatography (HPLC)

High Performance Thin Layer Chromatography (HPTLC)

Semi Preparative High Performance Liquid Chromatograph Combined with Gel Permeation Chromatograph (GPC)

Inductively Coupled Plasma Atomic Emission Spectrometer ( ICP- AES)

Fourier Transform Infra Red Spectrometer ( FTIR )

Universal Pilot Plant for Scaling up of ‘High Energy Materials (HEMs)

Test bed of 100 Ton Thrust capacity for static testing of propulsion systems

Automatic Parallel Synthesizer (APS)

- Versatile reaction system enables to carry out different reactions efficiently in parallel mode to screen and optimize the various unit processes.

- Provision of four parallel reactors - 50,125, 250 & 500ml capacity.

- Reactors work simultaneously & independently in the temp. range of -80°C to + 250°C with accuracy of ± 1°C.

Ultrasonic Reaction System (URS)

- Horn type flow cell reaction system, comprising of jacketed reactor, sound generator, transducers, agitator, ultrasonic flow cell, cylinder, thermostat/cryostat, pump etc. operated through PC.

- Ultrasonic processor - serial interface unit for control & monitoring of processes.

- Capacity of ultrasonic processor - ~ 20 KHz.

Thermal Screening Unit (TSU)

- Fully automatic insulated unit, consists of test cells, electric heater, thermocouple, pressure transducers, etc. operated through PC.

- Suitable unit for first step in-reaction hazards assessment.

- Screening at High temp. (~ 400°C) & pressure (~200 bar)

Thermal Analysis System (TAS)

- Fully automatic system, consisting of dual furnace, sensors, cooling system (Intercooler & CLN2), gas flow system, sample preparation system, electronic flow meter, gas cylinders.

- Pt/Ir material for furnace as resistant to oxidation with wide variety of samples including explosives.

- Provision of real time based scanning of samples with high heating (0.01 - 300°C/min) & cooling (0.01 – 150°C/min) rate over wide temp. range of -170°C to + 750°C.

Bench Scale Facility (BSF)

Single unit to perform experiments comprising of multiple reactors (50, 125, 250 & 500ml capacity) with thermostat/ cryostat, agitators, liquid dosing pumps, quenching vessels, reflux distillation under vacuum, filtration unit, gas scrubber, compressor, PLC/SCADA and PC.

An intermediate set-up between lab scale and pilot plant scale, useful to validate the process developed at lab level and generating data to design process equipments for pilot plant.

Micro reactor Based Continuous Nitration Plant

First time installed in HEMRL for nitration of liquid HEMs and the reaction time is reduced by 99%.

Online reaction monitoring system using ‘React-IR

Online reaction monitoring system using ‘React IR’ is useful to control & monitor the reaction the in-line without any physical sampling. The React IR probe station is having two parts namely React IR base station & the probe made of silver halide (AgX). The ReactIR base is a comprehensive and dedicated reaction analysis system. It is a react-time, insitu FT-IR instrument equipped with multi-bounce ATR (attenuated total reflectance) probes to monitor reactions under ambient and elevated pressures and temperatures that doesn’t require sample perturbation.

Integrated Sub-Zero Reaction System (ISZRS)

- ISZRS is comprising of Triple wall jacketed reactor (60 lit capacity), Filter reactor (50 lit capacity), Scrubber system, Heating/ Cooling unit (-90 to +150 ℃ with 2 nos. of auxilliary chillers) with Uninterupted Power Supply.

- The plant is fully automatic and process parameters are controlled through PLC and SACADA based control system. ISZRS is suitable for carrying out reaction at -70 to +130 ℃.

Universal Pilot Plant (UPP)

- UPP facility is equipped with advanced reactors, quenchers, feed modules, crystallizers, filtration units, vacuum driers, scrubbers, on-line nitrogen generator, effluent treatment plant and required essential utilities.

- The plant is fully automatic and process parameters are controlled through PLC and SACADA based control system. UPP is suitable for processing / development of high performance futuristic HEMs ranging from milligram to 20 kg batch levels hooked with precision control system and safety measures’

- Universal Pilot Plant (UPP) was inaugurated by Shri Manohar Parrikar, Honourable Defence Minister on 19th November 2015.

Thermal properties analyzer

Features

- It measures thermal diffusivity, specific heat and derives thermal conductivity of material with addition input of density.

- Thermal parameters can be measured from -1500C to 10000C temperature range.

- Thermal diffusivity can be measure in the range of 0.001 to 10 cm2 /sec.

- Thermal conductivity measurement range is 0.1 to 2000 W/m-K.

- Accuracy for thermal diffusivity measurement is < ±2%.

- Accuracy for specific heat and thermal conductivity measurement is < ±5%.

Applications

Thermal properties analyzer is used for thermal properties measurement of solid materials. It is based on flash technique and compliance to ASTM standard E1461. It is absolute method for thermal diffusivity measurement.

Dilatometer (Thermal expansion coefficient measurement)

Features

- The system is having a digital displacement transducer, which is an absolute device with no periodic calibration.

- Digital displacement transducer has minimum readability of 1µm.

- Digital displacement transducer can measure up to 25mm change in length.

- Thermal expansion can be measured from -1500C to 10000C temperature range.

- System is useful for linear thermal expansion coefficient (CTE) measurement.

- This system can be used for the variation of density with temperature

Applications

Dilatometer is used for thermal expansion measurement of solid materials. It compliance to ASTM standard E228 and D696.

High temperature calibration facility up to 30000 C

Features

- Temperature calibration range : 600 to 3000 0C

- Temperature Accuracy : ±0.25% of reading

- Cavity diameter : From 2.54mm to 25mm

- Time to reach 30000 C : ~20 Minutes

- Calibration Traceability : NIST

Applications

High temperature black body is the state of art facility for calibration of IR radiometers, multi colour pyrometers, heat flux sensors and thermal imaging cameras by radiation method.

Measurement of Ablation Rate

Features

- Oxyacetylene Based Method

- Ablation rate, Heat of ablation, Backwall temperature at constant heat flux measurement

- Variable Heat Flux from 100 W/cm2 to 800W/cm2

- Initial screening of thermal insulation material in R&D phase.

- Standard: ASTM E285

Applications

This facility is being used for Ablation/Erosion rate measurement of insulating materials used as insulators inside the rocket motors to protect the motors from high temperature during combustion of rocket propellant.

450 kV FLASH X Ray System

Flash X ray Radiography (FXR) is the one of the few methods for high speed radiography of fast moving objects. The emission of X rays being for very short duration therefore is called Flash X ray systems and the technique is called Flash Radiography.

The Flash X ray system provides short and intense pulses of X rays, making these systems ideal for high speed radiography. The Flash radiography provides unique possibility for keeping track of target-projectile interaction, during penetration process which is not possible by use of optical cameras as most target materials under investigation are opaque to light. Moreover, most of these phenomena are associated with intense light, dense smoke and debris which make their recording by optical cameras very difficult.

This laboratory possesses a 450 kV Flash X ray system, make Scandiflash, Sweden. The Flash X ray facility presently is fully operational with four numbers of X ray tube and Pulsers. The four X ray tube can be operated simultaneously or with proper per-fixed delay. Imaging is being done using digital radiography system, more specifically, a Computed Radiography (CR) system. The Computed Radiography makes the developing process much less time consuming part of the Flash X ray diagnostics.

Conditioning chamber (Temp Range: -60 0C to +80 0C, Dimensions:1.5 m X 1.5 m X 3m)