Infrastructure Facilities

Mechanical CAD/CAM Facility

This is a well-equipped mechanical facility for design, packaging and manufacture of electronic systems and LRUs. Computer aided design and analysis, Thermal and Structural analysis facilities are also available in this centre.

Antenna Test Facilities

Anechoic Chamber and open test range with automatic Antenna measurement capabilities are being used for testing different types of antennas and Radomes covering microwave & mm wave frequencies.

Environmental Engineering Facility

This facility consists of environmental chambers, bump and vibrations test set ups and is used for performing environmental tests on different electronic sub-systems and systems. These tests are carried out as per MIL standards and JSS-55555.

Sites

Simulation Testing and Evaluation Station (SITES) is acomprehensive facility for simulation, exhaustive testing and evaluation of EW subsystems being developed under various programmes of DLRL.

Class 1,00,000 Clean Room Facility at ELSEC

A clean room facility has been established at ELSEC for integration and evaluation of space-based payloads for space Projects of DLRL. This is a class 1,00,000 facility over a floor area of about 2000 sft. which can accommodate testing and integration of subsystems simultaneously. Within clean room facility, the class 100 Laminar flow tables are also provided for handling the module level and component level integration activities.

Curvilinear Test Facility at ELSEC

A Curvilinear Positioning System with an accuracy of 0.1 degree along with advance check out system is installed to test and evaluate ELINT system performance. This facility will be useful to measure Direction of Arrival (DoA) & accuracies in azimuth and elevation planes for an integrated ELINT Systems.

EMI/EMC Test Facility

The components, subsystems and integrated systems designed and developed by the Lab are subjected to Electromagnetic Interference / Electromagnetic Compatibility (EMI/EMC) tests for MIL-STD-461E/F. The facility has a 56x40x26 feet shielded Semi Anechoic chamber which is also equipped with Automated Emission Data Collection and Measurement System (AEDCMS) for automated Emission Measurements. Tests like CE 101, CE 102, RE 101, RE 102 and CE 106 can be conducted with the automated facilities. Also, this facility is equipped with Automated EMI Susceptibility Measurement System (AESMS) for Automatic Conducted / Radiated Susceptibility Measurements. Using this facility, Automated Tests like CS 101, RS 101, CS 114 and CS 115 and CS 116 are being carried out. This facility has Automated Radio Susceptibility Test (ARSTS) Set up for carrying out RS 103 test.

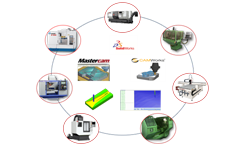

CNC CAM Facility

DLRL has a well-established CNC Centre for manufacturing of various microwave and millimetre wave components, antennas and housings, having intricate shapes and complex geometries with very high precision. This centre has eight CNC machines which includes 4-Axis Universal Milling, 3-Axis CNC Vertical Machining Centres, 3-Axis Vertical Milling, 4-Axis Turn-Mill, 2-Axis Flat Bed Lathe and 3-Axis CNC Router. Computer Aided Manufacturing (CAM) tools along with a dedicated Direct Numerical Control (DNC) are used to systematically generate the Job Set-Up sheets, Manufacturing Process Plans and finally generate Machine Tool Paths for realizing various complex jobs.

Rotating Platform

It is a unique test facility established in laboratory for the evaluation of EW systems. This can take a system vehicle with a weight of 30 tons, and can be used for DF accuracy measurement.

NATIONAL OPEN AIR RANGE (NOAR)

A Comprehensive EW Test Range is being established in Kurnool district of Andhra Pradesh catering to Simulation of Multi-threat scenario covering Communication & Radar bands and facility for testing of High Energy Laser Systems.