Infrastructure Facilities

Near-Field Diagnostic RCS Facility (NFDRF)

This is an RCS Range for Static RCS measurements (over 2-18 GHz) and Diagnostic Imaging of full-scale aircraft and other systems. The facility features a Precision Turntable of 40 ton rating, precision antenna positioners, and microwave instrumentation and data acquisition systems for RCS measurements.

The Data Processing Centre (DPC)

This facility houses a range of equipments and system level facilities for signature studies on Ground Vehicles and airborne targets in Vis-NIR and Thermal Infrared spectral domains. The equipments include Hyper-spectral Imaging Systems, Thermal Imaging Systems, IR imaging calibration sources and climatic chamber, Laser Scanning System, Spectro-radiometers and others.

Black Body Calibration Sources

Black Body Calibration Sources

Thermal Imagining Systems

Advanced Material Centre

This Facility houses a Chemical Synthesis Laboratory, supported by a range of instruments for materials characterization. These include Scanning Electron Microscope with EDS, X-ray Diffraction System, Atomic Force Microscopy, Vibrating Sample Magnetometer, Particle Size Analyzer, FTIR spectrophotometer, Spectrofluorometer, and others. It also houses Facilities for bulk production of ferrite materials, conducting polymer and nano-composites, equipped with Heavy-duty Hydraulic Press, Rubber Processing Unit, and Thermal Spray Unit. The centre is equipped with a number of environmental test facilities including weatherometer , solar chamber , climatic chamber, raintest chamber etc.

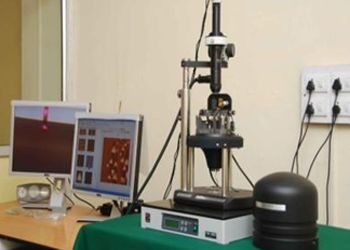

Vibrating Sample Magnetometer

Atomic Force Microscope

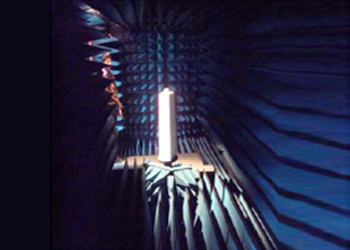

Anechoic Chamber and EM Characterization Facility

These facilities support the Laboratory test and development of Radar Absorbing materials and products. Base materials are characterized by their electrical parameters of permittivity and permeability at Microwave frequencies, and RAM products are measured for their Return Loss and RCS performance.

Microwave Instrumentation and Anechoic Chamber Facility

Microwave Instrumentation and Anechoic Chamber Facility

Radiation Imaging Facilities for Non Destructive Evaluation

Radiography Facilities established at DLJ comprise of Film & Digital Flat Panel Detector based Radiation Imaging capabilities utilizing X-ray, Gamma Ray & Neutron based Sources for Non Destructive Evaluation (NDE). X Ray Sources of upto 250 KVP, Gamma Ray Sources of Co-60, Ir-192 & Cs-137 and Neutron Sources of Cf-252 are available for investigations and provides complete spectrum of Radiography applications right from X-rays for lower thicknesses to Gamma Rays for higher thicknesses and neutrons for hydrogenous materials in metallic shields.

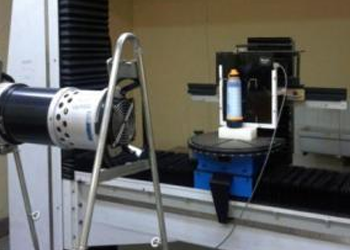

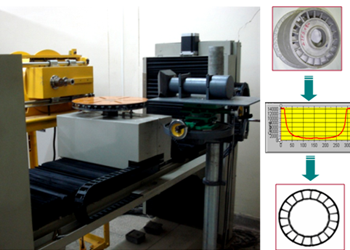

Gamma Ray based Computed Tomography Facility

Computed Tomography (CT) is an advanced Non Destructive Evaluation (NDE) technique which provides complete cross-sectional details of any scanned object. DLJ has established indigenously developed Technology based on Gamma Ray Transmission based Attenuation Measurements using Non Contact & Non Invasive Technique. The facility has capability to penetrate thick metallic assemblies & subsystems and provides complete internal structure visualization and exact details in 2D & 3D, irrespective of complexities in systems & assemblies.

Radiation Test & Calibration Facility

Semi-automatic gamma radiation test & calibration facility have been designed, developed and commissioned at Defence Laboratory Jodhpur (DLJ). The facility comprises of medium and high dose rate range setup using 30 Ci Cobalt-60 source in a portable remotely operated Techops camera and a 15000 Ci Co-60 source in a Tele-therapy machine. The radiation instruments can be positioned at any desired position using a computer controlled positioned. User friendly software helps in positioning the Device Under Test (DUT) at any desired dose rate or distance and acquire the data automatically. The test and calibration of radiation monitors is done as per ISO17025 and the Facilities and procedures are accredited by NABL.

Accelerated/Simulated Desert Environment Testing Facility

Extreme hot desert climate may severely affect the performance, reliability and life of Defence systems, this may lead to failure of mission critical components. An Accelerated Desert Environmental Test facility has been established to study long term and short term effects of extreme desert climate on Defence systems under simulated conditions. As part of this facility the Solar Radiation Chamber and Blowing Dust chamber have been installed, commissioned and operationalized complying to MIL Standards.

MEGH (Microwave ECM Generation Hub) Consists of

Pilot Plant for bulk production of Chaff material

Quality Control Lab

Finishing, Cutting, Packaging and Assembly Chamber

Indoor Microwave Chaff RCS Characterization Lab

BADRA (Blooming And Dynamic RCS Analysis Facility) Consists of

Chaff Firing Range (80m x 70m)

Counter Measure Dispensing System (CMDS)Chaff Firing Range (80m x 70m)

Chaff Pneumatic Blooming System

Mobile Dynamic RCS Measurement System