| S.No. | Name of the Item | Image |

|---|

| 1 | Free Space Measurement System |  Free Space Measurement System is a versatile, non destructive broadband electromagnetic characterization facility. A pair of dielectric lens mounted in a conical horn antenna provide plain wave illumination to sample. System is used for evaluation of reflection loss, transmission loss, permittivity & permeability of materials (sample size: 15x15cm) in 5 .85 -40 GHz frequency region at -20 oC to 1200 oC temperature using high & low temperature cells . Free Space Measurement System is a versatile, non destructive broadband electromagnetic characterization facility. A pair of dielectric lens mounted in a conical horn antenna provide plain wave illumination to sample. System is used for evaluation of reflection loss, transmission loss, permittivity & permeability of materials (sample size: 15x15cm) in 5 .85 -40 GHz frequency region at -20 oC to 1200 oC temperature using high & low temperature cells . |

| 2 | Quasi -Optical Measurement System |  Quasi -Optical Measurement System is a non destructive broadband electromagnetic characterization facility for 40 -110 GHz frequency region. It uses a pair of paraboloid reflectors with band specific transmitting /receiving antenna to provide plain wave illumination to sample. System is used for evaluation of reflection loss, transmission loss, permittivity & permeability of materials (sample size: 15x15cm) at room temperature. Quasi -Optical Measurement System is a non destructive broadband electromagnetic characterization facility for 40 -110 GHz frequency region. It uses a pair of paraboloid reflectors with band specific transmitting /receiving antenna to provide plain wave illumination to sample. System is used for evaluation of reflection loss, transmission loss, permittivity & permeability of materials (sample size: 15x15cm) at room temperature. |

| 3 | Waveguide and Co - axial Airline based Microwave Measurement Setup |  DMSRDE has Vector Network Analyzer based waveguide setup ( 3 .95 - 40GHz ), co -axial setup (110MHz to 18GHz) and dielectric probe ( 2 -18GHz) for evaluation of reflection loss, transmission loss, permittivity and permeability of materials at room temperature. These facilities use band specific rectangular (waveguide ), toroidal (co -axial ), square (dielectric probe) samples and can be used for evaluation of materials in the form of coatings, composites & fabrics DMSRDE has Vector Network Analyzer based waveguide setup ( 3 .95 - 40GHz ), co -axial setup (110MHz to 18GHz) and dielectric probe ( 2 -18GHz) for evaluation of reflection loss, transmission loss, permittivity and permeability of materials at room temperature. These facilities use band specific rectangular (waveguide ), toroidal (co -axial ), square (dielectric probe) samples and can be used for evaluation of materials in the form of coatings, composites & fabrics |

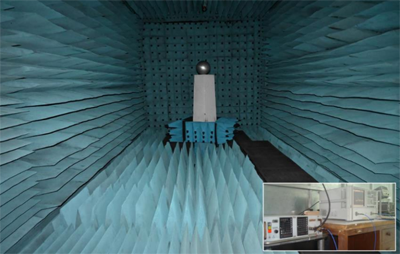

| 4 | Anechoic Chamber |  DMSRDE has an anechoic chamber with 30cm X 30cm quiet zone for the Radar Cross Section (RCS) measurements of components / flat panels in 2 to 40 GHz frequency region. The anechoic chamber is equipped with a computer controlled two axis target positioner for measurements at different azimuth and elevation angles . DMSRDE has an anechoic chamber with 30cm X 30cm quiet zone for the Radar Cross Section (RCS) measurements of components / flat panels in 2 to 40 GHz frequency region. The anechoic chamber is equipped with a computer controlled two axis target positioner for measurements at different azimuth and elevation angles . |

| 5 | Electromagnetic Shielding Measurement Setup |  The electromagnetic shielding effectiveness of composites / fabrics is evaluated using Vector Network Analyzer based setup consisting of dual TEM cell and flanged Co -axial fixture (as per ASTM D4935) in 100 MHz to 1 GHz frequency region The electromagnetic shielding effectiveness of composites / fabrics is evaluated using Vector Network Analyzer based setup consisting of dual TEM cell and flanged Co -axial fixture (as per ASTM D4935) in 100 MHz to 1 GHz frequency region |

| 6 | Computation Electromagnetics Facility |  DMSRDE has established rack server based Ninety - Six core high performance computing facility for electromagnetics modelling and simulations. This facility is extensively in use for modelling and simulation studies of electromagnetic absorbers, Frequency Selective Surfaces (FSSs ), Metamaterials, Cavities, various aero -components and other scattering problems using commercial time domain, frequency domain and hybrid electromagnetics solvers. DMSRDE has established rack server based Ninety - Six core high performance computing facility for electromagnetics modelling and simulations. This facility is extensively in use for modelling and simulation studies of electromagnetic absorbers, Frequency Selective Surfaces (FSSs ), Metamaterials, Cavities, various aero -components and other scattering problems using commercial time domain, frequency domain and hybrid electromagnetics solvers. |

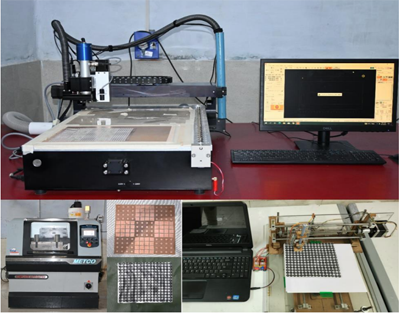

| 7 | Frequency Selective Surfaces Fabrication Facility |  Facilities for fabrication of Frequency Selective Surfaces (FSSs) and Metamaterials on rigid and flexible substrates are available for lab level fabrication. These computerized facilities cater for milling, drilling, cutting, screen printing, and printing as per electromagnetic design. Facilities for fabrication of Frequency Selective Surfaces (FSSs) and Metamaterials on rigid and flexible substrates are available for lab level fabrication. These computerized facilities cater for milling, drilling, cutting, screen printing, and printing as per electromagnetic design. |

| 8 | Cryogen Free Physical Properties Measurement System |  Cryogen free Physical Property Measurement System (PPMS) combines the latest cryogen -free technology with sophisticated measurement techniques to provide a versatile, powerful investigative device achieving low temperatures (2 oK) and high magnetic fields (up to ±9T) without the use of liquid Helium or nitrogen. This facility can be used for the characterization of materials for magnetic properties, AC susceptibility, DC resistivity, Hall coefficient, AC resistivity, Heat capacity, Thermal Transport, Seebeck coefficient, etc. Cryogen free Physical Property Measurement System (PPMS) combines the latest cryogen -free technology with sophisticated measurement techniques to provide a versatile, powerful investigative device achieving low temperatures (2 oK) and high magnetic fields (up to ±9T) without the use of liquid Helium or nitrogen. This facility can be used for the characterization of materials for magnetic properties, AC susceptibility, DC resistivity, Hall coefficient, AC resistivity, Heat capacity, Thermal Transport, Seebeck coefficient, etc. |

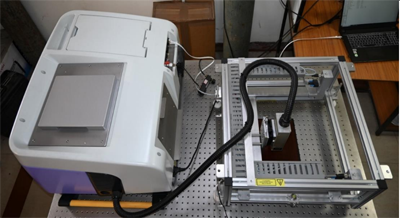

| 9 | THz Spectroscopy and Imaging System |  Terahertz (THz) Spectroscopy and Imaging System is used for material characterization in THz domain and structural defect analysis (NDT testing) for polymeric composites, RAS composites, UHMWPE composites etc. Spectroscopy is done in Transmission mode whereas THz imaging is done in Reflection mode. System covers the spectral range of 0 .06 to 4 THz with 1 GHz frequency resolution. Terahertz (THz) Spectroscopy and Imaging System is used for material characterization in THz domain and structural defect analysis (NDT testing) for polymeric composites, RAS composites, UHMWPE composites etc. Spectroscopy is done in Transmission mode whereas THz imaging is done in Reflection mode. System covers the spectral range of 0 .06 to 4 THz with 1 GHz frequency resolution. |

| 10 | Thermal Imagers |  Thermal Imagers operating in 3 -5µm and 8 -12µm spectral regions are used for assessing the thermal camouflage efficacy and measurement of emissivity of materials in these spectral regions. These imagers create image using infrared radiation emitted or reflected by the objects. These imagers can also be used for non -destructive testing of the materials . Thermal Imagers operating in 3 -5µm and 8 -12µm spectral regions are used for assessing the thermal camouflage efficacy and measurement of emissivity of materials in these spectral regions. These imagers create image using infrared radiation emitted or reflected by the objects. These imagers can also be used for non -destructive testing of the materials . |

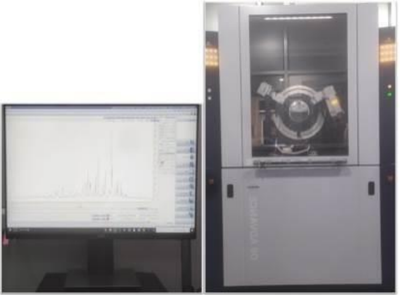

| 11 | X -Ray Diffractometer |  The Bruker D8 ADVANCE XRD is perfectly designed for all X -ray powder diffraction and scattering applications including traditional X-ray powder diffraction (XRD), Pair Distribution Function (PDF)analysis, Small and Wide Angle X-ray Scattering (SAXS, WAXS) at the temperature range of RT to 500 oC. XRD uses Copper XRay source (λ: 1.5 A) and has 0.01o angular accuracy. It can be used for Phase identification, Crystallinity information, and Lattice parameter determination. The Bruker D8 ADVANCE XRD is perfectly designed for all X -ray powder diffraction and scattering applications including traditional X-ray powder diffraction (XRD), Pair Distribution Function (PDF)analysis, Small and Wide Angle X-ray Scattering (SAXS, WAXS) at the temperature range of RT to 500 oC. XRD uses Copper XRay source (λ: 1.5 A) and has 0.01o angular accuracy. It can be used for Phase identification, Crystallinity information, and Lattice parameter determination. |

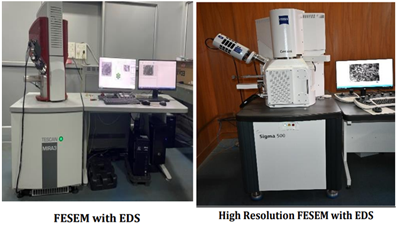

| 12 | Scanning Electron Microscopes |  Schottky Thermal Field Emitter based FESEM (TESCAN MIRA3) and High Resolution FESEM (ZEISS SIGMA 500) have 1.2nm and 0.8nm resolution respectively. Both FESEM are equipped with EDS and have magnification X10 to X1000000. These facilities can be used for Topographical, Morphological, Compositional and elemental (qualitative and quantitative) analysis of specimen. Schottky Thermal Field Emitter based FESEM (TESCAN MIRA3) and High Resolution FESEM (ZEISS SIGMA 500) have 1.2nm and 0.8nm resolution respectively. Both FESEM are equipped with EDS and have magnification X10 to X1000000. These facilities can be used for Topographical, Morphological, Compositional and elemental (qualitative and quantitative) analysis of specimen. |

| 13 | Lyophilizer |  Lyophilizer is used for lyophilization or cryodesiccation processes, popularly known as freeze drying process, which remove the ice by sublimation. It can achieve upto -55 oC temperature while maintain the vacuum level Lyophilizer is used for lyophilization or cryodesiccation processes, popularly known as freeze drying process, which remove the ice by sublimation. It can achieve upto -55 oC temperature while maintain the vacuum level |

| 14 | Particle Size Analyzer |  Zetasizer Particle Size Analyzer is used to measure the particle size of dispersed systems from 0 .3 nanometer to 10 micrometers in diameter, using classic 90 o as well as multi -angle Dynamic Light Scattering technique. This system can also be used to analyze particle mobility and charge (Zeta potential) using the technique of Electrophoretic Light Scattering, and the molecular weight of particles in solution using Static Light Scattering. Zetasizer Particle Size Analyzer is used to measure the particle size of dispersed systems from 0 .3 nanometer to 10 micrometers in diameter, using classic 90 o as well as multi -angle Dynamic Light Scattering technique. This system can also be used to analyze particle mobility and charge (Zeta potential) using the technique of Electrophoretic Light Scattering, and the molecular weight of particles in solution using Static Light Scattering. |

| 15 | Optical Contact Angle Measurement System (OCA 200 ) |  OCA -200 Optical Contact Angle Measurement System is equipped with high resolution optics & 6 .5X zoom lens and is used to study the wetting behavior of solid surfaces using double dosing (nanolitre and picolitre) system. This system can also be used for determination of surface energy of the solids and work of adhesion by measuring the contact angles of multiple test liquids . OCA -200 Optical Contact Angle Measurement System is equipped with high resolution optics & 6 .5X zoom lens and is used to study the wetting behavior of solid surfaces using double dosing (nanolitre and picolitre) system. This system can also be used for determination of surface energy of the solids and work of adhesion by measuring the contact angles of multiple test liquids . |

| 16 | Electrochemical Workstation |  The Multi Autolab M204 is a multi -channel potentiostat/galvanostat instrument to perform the electrochemical measurements upto 10A current on each channel simultaneously. This instrument can be utilized to perform a CV, linear sweep voltammetry, GCD, chronoamperometry, and EIS analysis for the understanding of electrochemical characteristics of energy storage & conversion devices and for the study of reaction kinetics & corrosion properties. The Multi Autolab M204 is a multi -channel potentiostat/galvanostat instrument to perform the electrochemical measurements upto 10A current on each channel simultaneously. This instrument can be utilized to perform a CV, linear sweep voltammetry, GCD, chronoamperometry, and EIS analysis for the understanding of electrochemical characteristics of energy storage & conversion devices and for the study of reaction kinetics & corrosion properties. |

| 17 | Electrospinning Machine |  Electrospinning Machine is capable for co - electrospinning of two polymeric solutions simultaneously to produce core -shell fibers. With the help of this machine, fibers with diameter in the range of few nanometer to few hundreds of nanometer can be produced by tuning the viscosity, electric field and flow rate. Both solid and hollow polymeric fibers as well as metallic and metal oxide fibers with narrow diameter distributions can be made using this machine . Electrospinning Machine is capable for co - electrospinning of two polymeric solutions simultaneously to produce core -shell fibers. With the help of this machine, fibers with diameter in the range of few nanometer to few hundreds of nanometer can be produced by tuning the viscosity, electric field and flow rate. Both solid and hollow polymeric fibers as well as metallic and metal oxide fibers with narrow diameter distributions can be made using this machine . |

| 18 | Humidity Cabinet for Corrosion Testing |  The Humidity cabinet is used to study the corrosivity of materials or the effects of residual contaminants in materials under controlled humid environments . The Humidity cabinet is used to study the corrosivity of materials or the effects of residual contaminants in materials under controlled humid environments . |

| 19 | Accelerated Weathering Tester |  Accelerated weathering tester simulates the extreme weather conditions using special environmental chambers and instruments that speed up the weathering process. Environmental effects can cause a change in color, cracking, corrosion, and deterioration of a product ’s exterior and interior. Accelerated weathering tester simulates the extreme weather conditions using special environmental chambers and instruments that speed up the weathering process. Environmental effects can cause a change in color, cracking, corrosion, and deterioration of a product ’s exterior and interior. |

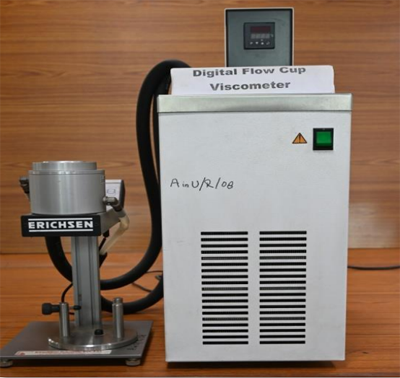

| 20 | Digital Flow Cup Viscometer |  Viscosity is a measure of how resistant a paint is to spreading. The cup viscometer determines the flow property of paint samples in terms of the kinematic viscosity at different temperatures. Viscosity is a measure of how resistant a paint is to spreading. The cup viscometer determines the flow property of paint samples in terms of the kinematic viscosity at different temperatures. |

| 21 | Cupping Tester |  The Cupping tester performs a cupping test on coated mild steel panels to define the resistance of paint, varnish or related products to cracking and /or detachment from a metal substrate when subjected to gradual deformation by indentation under standard Conditions. The test is a “pass / fail” test by testing to a specified depth or defining the minimum depth at which a coating fails by gradually increasing the indentation . The Cupping tester performs a cupping test on coated mild steel panels to define the resistance of paint, varnish or related products to cracking and /or detachment from a metal substrate when subjected to gradual deformation by indentation under standard Conditions. The test is a “pass / fail” test by testing to a specified depth or defining the minimum depth at which a coating fails by gradually increasing the indentation . |

| 22 | Dry Abrasion Tester |  The abrasive is allowed to fall from a specified height through a guide tube onto the coated panel until the substrate becomes visible. The amount of abrasive per unit film thickness is reported as the abrasion resistance of the coating on the panel. Both silica sand or silicon carbide can be used as a abrasive materials . The abrasive is allowed to fall from a specified height through a guide tube onto the coated panel until the substrate becomes visible. The amount of abrasive per unit film thickness is reported as the abrasion resistance of the coating on the panel. Both silica sand or silicon carbide can be used as a abrasive materials . |

| 23 | Nano eNabler |  Nano eNabler is a cantilever based device which can handle samples like colloidal nanoparticles dispersions etc. and is able to print on the substrates such as silicon, glass, gold, silanes, PDMS, hydrogels and plastics etc. with high resolution at a faster speed. It is able to produce ultra micron or nanoarray of up to 10 -50 domains or more with resolution better than 20nm on a substrate of size 50mm x 50mm . Nano eNabler is a cantilever based device which can handle samples like colloidal nanoparticles dispersions etc. and is able to print on the substrates such as silicon, glass, gold, silanes, PDMS, hydrogels and plastics etc. with high resolution at a faster speed. It is able to produce ultra micron or nanoarray of up to 10 -50 domains or more with resolution better than 20nm on a substrate of size 50mm x 50mm . |

| 24 | UV -Vis -NIR Spectrophotometer |  UV -Vis -NIR Spectrophotometer is capable to measure Transmission, reflectance and absorption parameters of solid, liquid and thin films in UV, Visible and Near IR spectral regions. It is also capable of measuring the variable angle specular reflectance and diffuse reflectance . UV -Vis -NIR Spectrophotometer is capable to measure Transmission, reflectance and absorption parameters of solid, liquid and thin films in UV, Visible and Near IR spectral regions. It is also capable of measuring the variable angle specular reflectance and diffuse reflectance . |

| 25 | Photoluminescence and Electroluminescence Spectrometer |  Computer controlled, time resolved photoluminescence and electroluminescence spectrometer is used to characterize the photoluminescence, electroluminescence, exponential decay, lifetime distribution, spatial mapping of lifetime and anisotropy of various nanocrystalline materials, both dispersed in the solvents and deposited on the substrate, organic liquids and inorganic materials . Computer controlled, time resolved photoluminescence and electroluminescence spectrometer is used to characterize the photoluminescence, electroluminescence, exponential decay, lifetime distribution, spatial mapping of lifetime and anisotropy of various nanocrystalline materials, both dispersed in the solvents and deposited on the substrate, organic liquids and inorganic materials . |

| 26 | Pour Point apparatus |  The Pour point apparatus examines the fluidity of fluids /lubricants under extreme low temperature (upto -80°C) with an accuracy of ±2°C. The required minimum sample size is 50 ml. The Pour point apparatus examines the fluidity of fluids /lubricants under extreme low temperature (upto -80°C) with an accuracy of ±2°C. The required minimum sample size is 50 ml. |

| 27 | Heat Capacity Apparatus |  Nanofluid Heat Capacity Apparatus is a tool to study the thermo -physical properties of different nano - fluids as a function of temperature and concentration. This apparatus requires 250 ml of liquid sample to measure the specific heat in temperature range of RT to 70°C . Nanofluid Heat Capacity Apparatus is a tool to study the thermo -physical properties of different nano - fluids as a function of temperature and concentration. This apparatus requires 250 ml of liquid sample to measure the specific heat in temperature range of RT to 70°C . |

| 28 | Breakdown voltage tester |  Breakdown voltage tester is used to measure the breakdown voltage of the electrically insulating oil in the range of 1 to 100kV at room temperature. Breakdown voltage tester is used to measure the breakdown voltage of the electrically insulating oil in the range of 1 to 100kV at room temperature. |

| 29 | Nanofluid interferometer |  Nanofluid interferometer is a tool to optimize the concentration of nanoparticles in liquids. In this instrument, Ultrasound waves of known frequency are produced by a Piezo - Electric transducer and its wavelength is measured with digital micrometer within temperature range RT to 90 0 C . Nanofluid interferometer is a tool to optimize the concentration of nanoparticles in liquids. In this instrument, Ultrasound waves of known frequency are produced by a Piezo - Electric transducer and its wavelength is measured with digital micrometer within temperature range RT to 90 0 C . |

| 30 | High pressure reactor |  High pressure reactor system with 750ml capacity is designed to attain 2500 psi pressure. It has provision of in -situ stirring and precise temperature control upto 250 o C . The reactor system can facilitate various kind of chemical reactions like polymerization, hydrogenation and oxidation to synthesize variety of organic and inorganic compounds. High pressure reactor system with 750ml capacity is designed to attain 2500 psi pressure. It has provision of in -situ stirring and precise temperature control upto 250 o C . The reactor system can facilitate various kind of chemical reactions like polymerization, hydrogenation and oxidation to synthesize variety of organic and inorganic compounds. |

| 31 | Bomb Calorimeter |  Bomb Calorimeter facility (Parr 6200 Calorimeter) is a microprocessor controlled, isoperibol oxygen bomb calorimeter based testing facility for evaluation of energy content of liquid fuels (sample size: 0 .5gm ), with the maximum calorific value test range up to 12000 cal /gm . Bomb Calorimeter facility (Parr 6200 Calorimeter) is a microprocessor controlled, isoperibol oxygen bomb calorimeter based testing facility for evaluation of energy content of liquid fuels (sample size: 0 .5gm ), with the maximum calorific value test range up to 12000 cal /gm . |

| 32 | Ultra low temperature Kinematic Viscosity Bath |  Ultra low temperature kinematic viscosity bath facility is used to study the kinematic viscosity of any fluid, oil, fuels and lubricant in the temperature range of RT to -60 0 C. The required sample size is 50ml . Ultra low temperature kinematic viscosity bath facility is used to study the kinematic viscosity of any fluid, oil, fuels and lubricant in the temperature range of RT to -60 0 C. The required sample size is 50ml . |

| 33 | Corrosion Resistance Test Facility |  Corrosion resistance test facility can evaluate the performance of finished products /components (Max. size 250mmX100mm) in corrosive environment or field conditions. The test apparatus is manufactured as per ASTM B -117 and is used for Corrosion Studies on finished products. Corrosion resistance test facility can evaluate the performance of finished products /components (Max. size 250mmX100mm) in corrosive environment or field conditions. The test apparatus is manufactured as per ASTM B -117 and is used for Corrosion Studies on finished products. |

| 34 | Climate Chamber |  Programmable Climate Chamber is used for conditioning the product at temperatures in the range of -50oC to +50oC. This serves the purpose of testing of material /product ’s performance under variable temperature conditions. The Climate Chamber is used for Environmental testing for thermal cyclic load, Extreme low - temperature simulations studies, etc . Programmable Climate Chamber is used for conditioning the product at temperatures in the range of -50oC to +50oC. This serves the purpose of testing of material /product ’s performance under variable temperature conditions. The Climate Chamber is used for Environmental testing for thermal cyclic load, Extreme low - temperature simulations studies, etc . |

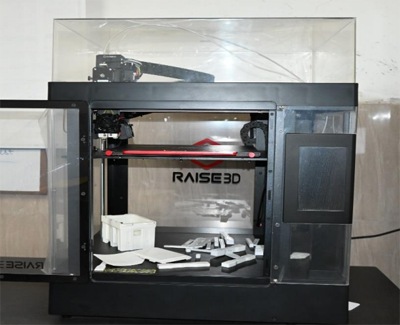

| 35 | 3 -D Printer |  Fused Deposition Modeling (FDM) based 3-D printer is used for Rapid Prototyping of products using plastic materials (PC /PLA /ABS) of a size upto 1 ’x1 ’x1’ with 100 µm accuracy and layer resolution of 20 µm. The system can be used for conceptual design validation, Rapid Prototyping and small component manufacturing . Fused Deposition Modeling (FDM) based 3-D printer is used for Rapid Prototyping of products using plastic materials (PC /PLA /ABS) of a size upto 1 ’x1 ’x1’ with 100 µm accuracy and layer resolution of 20 µm. The system can be used for conceptual design validation, Rapid Prototyping and small component manufacturing . |

| 36 | Ball mill |  Ball mill is used for crushing, grinding and homogeneously mixing the raw material powder into extremely fine form. The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with alumina balls. Ball mill is also provided with leak proof lead and dummy lid with perforation front for easy loading and unloading of the powder . Ball mill is used for crushing, grinding and homogeneously mixing the raw material powder into extremely fine form. The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with alumina balls. Ball mill is also provided with leak proof lead and dummy lid with perforation front for easy loading and unloading of the powder . |

| 37 | Hydraulic Press |  Hydraulic Press of 5 Tons capacity is used for extrusion of ceramic in the required shape using the die. Ram rate of the press can be accurately controlled in the range of 40 to 120 mm /min to meet the fabrication requirements. Hydraulic Press of 5 Tons capacity is used for extrusion of ceramic in the required shape using the die. Ram rate of the press can be accurately controlled in the range of 40 to 120 mm /min to meet the fabrication requirements. |

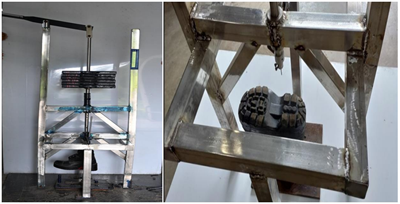

| 38 | Furnace |  Computer Controlled Electric Furnace of chamber dimensions 400 mm x 400mm x 400mm is used for sintering of ceramics. The extruded green ceramic is sintered at a temperature, which can be set up to 1410 oC with ±2° C uniformity, to achieve the required strength. Computer Controlled Electric Furnace of chamber dimensions 400 mm x 400mm x 400mm is used for sintering of ceramics. The extruded green ceramic is sintered at a temperature, which can be set up to 1410 oC with ±2° C uniformity, to achieve the required strength. |

| 39 | Penetration Test Machine for Anti - nail Boots |  This machine is used for checking the penetration resistance capability of inserts employed in the Anti -Nail Boots. A stationary platform is provided to hold the sample (insert or boot) at the bottom. Weight, which can be varied according to requirement, is attached with the nail. The test nail having specific geometry, prepared according to Indian standard IS 17275 (part 2): 2019- “Perforation Resistant Inserts for Protection of Feet – Specifications ”, is mounted on movable block. Nail along with weight is dropped from the required height on the test sample to check the penetration resistant capability . This machine is used for checking the penetration resistance capability of inserts employed in the Anti -Nail Boots. A stationary platform is provided to hold the sample (insert or boot) at the bottom. Weight, which can be varied according to requirement, is attached with the nail. The test nail having specific geometry, prepared according to Indian standard IS 17275 (part 2): 2019- “Perforation Resistant Inserts for Protection of Feet – Specifications ”, is mounted on movable block. Nail along with weight is dropped from the required height on the test sample to check the penetration resistant capability . |

| 40 | Synthesis Reactor (10 Lite |  Fully instrumented and SCADA operation enabled synthesis reactor of 10 liter capacity is used to carry out the synthesis of PDMS from dichlorodimethylsilane and sodium under precisely controlled reaction conditions under Argon /Nitrogen environment at a temperature, which can be set in the range of RT to 200°C. All parts that come in contact with corrosive chlorosilane are made up off Hastelloy C -22. Fully instrumented and SCADA operation enabled synthesis reactor of 10 liter capacity is used to carry out the synthesis of PDMS from dichlorodimethylsilane and sodium under precisely controlled reaction conditions under Argon /Nitrogen environment at a temperature, which can be set in the range of RT to 200°C. All parts that come in contact with corrosive chlorosilane are made up off Hastelloy C -22. |

| 41 | PCS Synthesis Reactors (02 Liter & 10 Liter) |  Polycarbosilane (PCS) synthesis reactors (02 liter and 10 liter capacity) are used to carry out the synthesis of PCS from PDMS under precisely controlled reaction conditions. These fully instrumented & SCADA operation enabled reactors are made using SS 316L can attain pressure in the range of 100mbar - 1 .5 bar and temperatures up to 500°C. Polycarbosilane (PCS) synthesis reactors (02 liter and 10 liter capacity) are used to carry out the synthesis of PCS from PDMS under precisely controlled reaction conditions. These fully instrumented & SCADA operation enabled reactors are made using SS 316L can attain pressure in the range of 100mbar - 1 .5 bar and temperatures up to 500°C. |

| 42 | Fourier Transform Infrared Spectroscopy (Far IR – Mid IR) with Attenuated Total Reflectance |  The Fourier Transform Infrared Spectroscopy facility (PerkinElmer FRONTIER FTIR) has measurement range of 30 - 8300 cm - 1 in both transmission and reflectance modes. It is equipped with ZnSe, Ge, Diamond based Attenuated Total Reflectance accessories apart from all varieties of Specular Reflectance and Diffused Reflectance facilities for all types of samples like solid, liquid, paste, film, fiber, composites etc. Instrument can be used for fundamental compositional analysis of chemical compounds including Silanes, Siloxanes, Carbosilanes etc. along with the quality inspection of raw materials The Fourier Transform Infrared Spectroscopy facility (PerkinElmer FRONTIER FTIR) has measurement range of 30 - 8300 cm - 1 in both transmission and reflectance modes. It is equipped with ZnSe, Ge, Diamond based Attenuated Total Reflectance accessories apart from all varieties of Specular Reflectance and Diffused Reflectance facilities for all types of samples like solid, liquid, paste, film, fiber, composites etc. Instrument can be used for fundamental compositional analysis of chemical compounds including Silanes, Siloxanes, Carbosilanes etc. along with the quality inspection of raw materials |

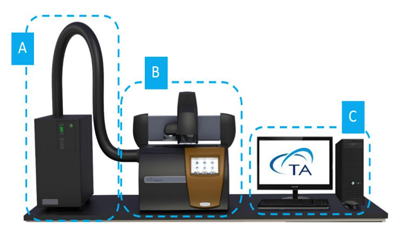

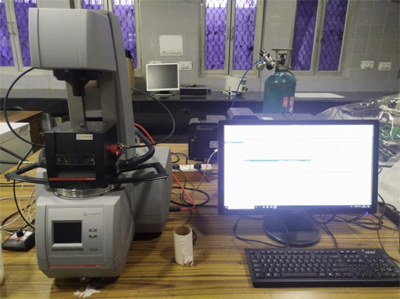

| 43 | Modulated Differential Scanning Calorimetry (MDSC ) |  Differential Scanning Calorimetry (TA Instruments Discovery DSC25) is used to analyze the thermal transformations (Tg, melting, oxidation, crosslinking, decomposition, etc.) in polymers. It measures endothermic and exothermic processes such as the glass transition (Tg ), melting, crystallization, cure reactions, the onset of oxidation, and heat of transitions (enthalpy ), etc. It is widely used for characterization of several class of materials like, polymers, pharmaceuticals, foods, bio -materials, organic and inorganic materials, etc. in the temperature range of -90°C to 700°C (heating rate: 0 .01 to 200°C /min, cooling rate: 0 .02 to 100°C /min ) Differential Scanning Calorimetry (TA Instruments Discovery DSC25) is used to analyze the thermal transformations (Tg, melting, oxidation, crosslinking, decomposition, etc.) in polymers. It measures endothermic and exothermic processes such as the glass transition (Tg ), melting, crystallization, cure reactions, the onset of oxidation, and heat of transitions (enthalpy ), etc. It is widely used for characterization of several class of materials like, polymers, pharmaceuticals, foods, bio -materials, organic and inorganic materials, etc. in the temperature range of -90°C to 700°C (heating rate: 0 .01 to 200°C /min, cooling rate: 0 .02 to 100°C /min ) |

| 44 | Rheometer |  A rheometer is used to measure the flow and deformation of materials w.r.t. temperature, time, and atmosphere when stress is applied. This equipment is capable of performing sophisticated rheological tests using cone - plate and parallel - plate measuring systems from room temperature to 450 oC under torque range of 1nNm to 230 mNm and force range of 0 .001 to 50 N . A rheometer is used to measure the flow and deformation of materials w.r.t. temperature, time, and atmosphere when stress is applied. This equipment is capable of performing sophisticated rheological tests using cone - plate and parallel - plate measuring systems from room temperature to 450 oC under torque range of 1nNm to 230 mNm and force range of 0 .001 to 50 N . |

| 45 | Pyrolysis Furnace (1800°C) |  Pyrolysis furnace is installed at DMSRDE to carry out the pyrolysis of stabilized polycarbosilane fibers. This furnace with Retort size of 400 x 400 x 900 mm has the capability to carry out the pyrolysis under H 2, BCl 3, N 2 /Ar, and vacuum (10 -2 mbar) up to 1800°C temperature. Pyrolysis furnace is installed at DMSRDE to carry out the pyrolysis of stabilized polycarbosilane fibers. This furnace with Retort size of 400 x 400 x 900 mm has the capability to carry out the pyrolysis under H 2, BCl 3, N 2 /Ar, and vacuum (10 -2 mbar) up to 1800°C temperature. |

| 46 | Gel Permeation Chromatography (GPC) System |  A Gel Permeation Chromatography system is used to determine molecular weight and molecular weight distribution of polymers. The system is equipped with three detectors namely refractive index, light scattering and viscometry and system works in the temperature range from RT to 60 oC and has independent temperature control with each detector to ensure high level of precision and reproducibility. Autosampler enables the GPC system to analyze 120 number of samples in one go A Gel Permeation Chromatography system is used to determine molecular weight and molecular weight distribution of polymers. The system is equipped with three detectors namely refractive index, light scattering and viscometry and system works in the temperature range from RT to 60 oC and has independent temperature control with each detector to ensure high level of precision and reproducibility. Autosampler enables the GPC system to analyze 120 number of samples in one go |

| 47 | Spinning System |  In order to melt spin polycarbosilane and metallo -polycarbosilane presursors into fibers under controlled pressure, temperature and atmosphere condition a spinning system has been established. Chamber can reach vacuum level up to 10 - 2 mbar and temperature up to 70°C. Max temperature of melt chamber is 400°C and hydraulic pressure can reach up to 25bar. Spinneret disc with 1, 25, 100 & 200 nos. of 250 µm diameter holes are available. The system has option of moving winding drum of 100, 120, 150, 200 and 250 mm diameter of 300 mm length which rotates up to 500 RPM and can move in X, Y and Z directions. In order to melt spin polycarbosilane and metallo -polycarbosilane presursors into fibers under controlled pressure, temperature and atmosphere condition a spinning system has been established. Chamber can reach vacuum level up to 10 - 2 mbar and temperature up to 70°C. Max temperature of melt chamber is 400°C and hydraulic pressure can reach up to 25bar. Spinneret disc with 1, 25, 100 & 200 nos. of 250 µm diameter holes are available. The system has option of moving winding drum of 100, 120, 150, 200 and 250 mm diameter of 300 mm length which rotates up to 500 RPM and can move in X, Y and Z directions. |

| 48 | Thermo -gravimetric Mass Spectrometer (TGMS) |  TGMS instrument (PerkinElmer TGA8000 with PerkinElmer CLARUS SQ8 MS) with 48 positions Auto -sampler is used to study the decomposition behaviour of polymeric materials and to analyse the pyrolyzed gases of the materials. Instrument has temperature range of RT - 1200 oC and studies can be carried out under Air, Oxygen, CO2, Helium, Argon and Nitrogen atmosphere using the Balance of capacity 1300 mg with 0 .1 micro gram sensitivity . TGMS instrument (PerkinElmer TGA8000 with PerkinElmer CLARUS SQ8 MS) with 48 positions Auto -sampler is used to study the decomposition behaviour of polymeric materials and to analyse the pyrolyzed gases of the materials. Instrument has temperature range of RT - 1200 oC and studies can be carried out under Air, Oxygen, CO2, Helium, Argon and Nitrogen atmosphere using the Balance of capacity 1300 mg with 0 .1 micro gram sensitivity . |

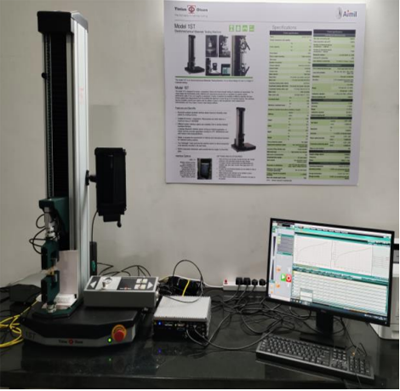

| 49 | Universal Testing Machine (UTM ) |  UTM instrument (1ST Tinius Olsen) is used to determine the mechanical properties e.g. tensile strength and tensile modulus of single filament and composites. UTM is equipped with Load Cells of 5N, 25N, 100N and 1kN with Non -Contact type Extensometer and Pneumatic Grips. Max cross head travel is 755mm . UTM instrument (1ST Tinius Olsen) is used to determine the mechanical properties e.g. tensile strength and tensile modulus of single filament and composites. UTM is equipped with Load Cells of 5N, 25N, 100N and 1kN with Non -Contact type Extensometer and Pneumatic Grips. Max cross head travel is 755mm . |

| 50 | Chemical Vapor Deposition (CVD) Facility |  Customized CVD facility of Hot Zone diameter 300mm and height 400mm has been created to deposit ceramic coatings on C /SiC composites for improving their oxidation and erosion performance. This facility can also be used for deposition of different types of ceramic coatings like SiC, PyC, SiO 2, BN, TaC etc. on a variety of substrates viz. fibers, fabric, preforms and shaped articles. Operating temperature of the system is in the range of 500 -1700 oC and vacuum can be maintained in the range of 0.2 -200 mbar. Customized CVD facility of Hot Zone diameter 300mm and height 400mm has been created to deposit ceramic coatings on C /SiC composites for improving their oxidation and erosion performance. This facility can also be used for deposition of different types of ceramic coatings like SiC, PyC, SiO 2, BN, TaC etc. on a variety of substrates viz. fibers, fabric, preforms and shaped articles. Operating temperature of the system is in the range of 500 -1700 oC and vacuum can be maintained in the range of 0.2 -200 mbar. |

| 51 | Vacuum Hot Pressing Facility |  Vacuum Hot Pressing facility has been created to fabricate ceramic powder based products. Different types of ceramic powders such as SiC, B4C, ZrB2, SiO2, Al2O3, etc. can be pressed to fabricate cylindrical, square and rectangle shaped article s. Operating temperature of the press is 500 -2300 oC maximum pressing load of 75 Ton can be applied. Hot Zone of diameter 300mm & height 200mm can attain operating vacuum in the range of 1x10 - 6 mbar – 900 mbar Vacuum Hot Pressing facility has been created to fabricate ceramic powder based products. Different types of ceramic powders such as SiC, B4C, ZrB2, SiO2, Al2O3, etc. can be pressed to fabricate cylindrical, square and rectangle shaped article s. Operating temperature of the press is 500 -2300 oC maximum pressing load of 75 Ton can be applied. Hot Zone of diameter 300mm & height 200mm can attain operating vacuum in the range of 1x10 - 6 mbar – 900 mbar |

| 52 | BET Surface Area Analyzer |  BET Surface Area Analyzer is used to measure the specific surface area, micro pore volume, total pore volume and average pore width. The surface area evaluation is based on BET theory using N 2 gas as adsorbate on samples at 77K. Pore volume is measured from nitrogen adsorption isotherms at 77K on samples at relative pressure of close to unity (0.99994). The sample weight required is 0 .02 gm BET Surface Area Analyzer is used to measure the specific surface area, micro pore volume, total pore volume and average pore width. The surface area evaluation is based on BET theory using N 2 gas as adsorbate on samples at 77K. Pore volume is measured from nitrogen adsorption isotherms at 77K on samples at relative pressure of close to unity (0.99994). The sample weight required is 0 .02 gm |

| 53 | Gas Chromatography |  Gas Chromatography is used for the separation, identification, and determination of the amount of separate compounds in a mixture. It has two phases: Stationary phase & Mobile phase. Operating temperature can be controlled in the range of 7 - 400 0 C. Gas Chromatography is used for the separation, identification, and determination of the amount of separate compounds in a mixture. It has two phases: Stationary phase & Mobile phase. Operating temperature can be controlled in the range of 7 - 400 0 C. |

| 54 | Mooney viscometer |  The Mooney viscometer is an instrument used for measuring the Mooney viscosity of rubbers. it contains a rotating spindle and heated dies, the substance encloses and overflows the spindle, and the Mooney viscosity is calculated from the torque on the spindle. Instrument has measuring range of 2 to 200mu The Mooney viscometer is an instrument used for measuring the Mooney viscosity of rubbers. it contains a rotating spindle and heated dies, the substance encloses and overflows the spindle, and the Mooney viscosity is calculated from the torque on the spindle. Instrument has measuring range of 2 to 200mu |

| 55 | Diffusion Test Apparatus |  Diffusion Test Apparatus is used for the screening test of permeable Individual Protective Equipment (IPEs) material through 1 -3 Di - Chloro propane break through time (DCP -BTT). DCP is nontoxic and simulant of sulfur mustard. Diffusion Test Apparatus is used for the screening test of permeable Individual Protective Equipment (IPEs) material through 1 -3 Di - Chloro propane break through time (DCP -BTT). DCP is nontoxic and simulant of sulfur mustard. |

| 56 | Visual Melting Range Apparatus |  Visual Melting Range Apparatus is used for the identification of the melting range of various synthetic textile fibres . Sample of 5 -10 mg quantity is required for measurement and heating rate is 1°C per minute Visual Melting Range Apparatus is used for the identification of the melting range of various synthetic textile fibres . Sample of 5 -10 mg quantity is required for measurement and heating rate is 1°C per minute |

| 57 | Flammability Tester |  Flammability Tester is used for the evaluation of flammability of textile fabrics. In this test, the fabric specimen is held at an angle of 45 0 to the horizontal and a standardized flame is applied to the surface near the lower end for 1 second. The time required for flaming a distance of 127 mm up the fabric is measured. Flammability Tester is used for the evaluation of flammability of textile fabrics. In this test, the fabric specimen is held at an angle of 45 0 to the horizontal and a standardized flame is applied to the surface near the lower end for 1 second. The time required for flaming a distance of 127 mm up the fabric is measured. |

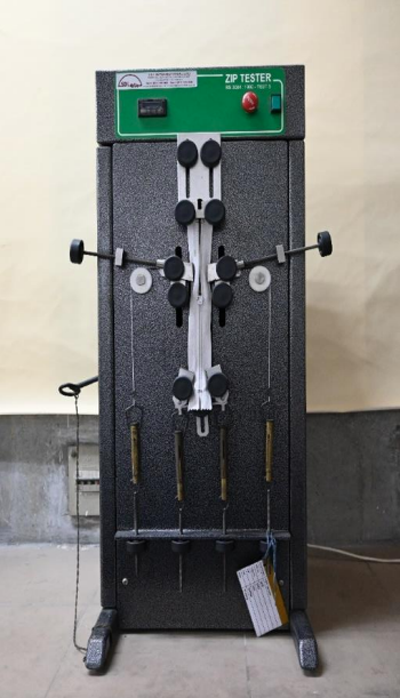

| 58 | Zip Tester |  A zip tester of capacity 0 -7 kg /cm 2 and 0 -35 kg /cm 2 is used to test the zip reciprocating movement of the slider under the lateral and longitudinal forces for a specific number of cycles. Tests are carried out as per IS :1060 (part - I). A zip tester of capacity 0 -7 kg /cm 2 and 0 -35 kg /cm 2 is used to test the zip reciprocating movement of the slider under the lateral and longitudinal forces for a specific number of cycles. Tests are carried out as per IS :1060 (part - I). |

| 59 | Bursting Strength Tester |  Bursting Strength Tester of capacity 0 -7 kg /cm 2 and 0 - 35 kg /cm2 is used to determine the bursting strength of a variety of materials. It is motor - driven system for increasing the fluid displacement under the rubber diaphragm at a specified rate and automatically lowers the pressure down and stops the motor when the test is completed. Tests are carried out as per IS :1060 (part - I) Bursting Strength Tester of capacity 0 -7 kg /cm 2 and 0 - 35 kg /cm2 is used to determine the bursting strength of a variety of materials. It is motor - driven system for increasing the fluid displacement under the rubber diaphragm at a specified rate and automatically lowers the pressure down and stops the motor when the test is completed. Tests are carried out as per IS :1060 (part - I) |

| 60 | Softness Tester |  Softness Tester is designed for testing coated fabrics and other soft materials such as leather. Deflection of the material of size 20 mm X 100 mm, while clamped above an aperture of a known diameter, is measured when subjected to a specific load applied by a pin of a small diameter as per test standard IULTCS. IUP 136 Softness Tester is designed for testing coated fabrics and other soft materials such as leather. Deflection of the material of size 20 mm X 100 mm, while clamped above an aperture of a known diameter, is measured when subjected to a specific load applied by a pin of a small diameter as per test standard IULTCS. IUP 136 |

| 61 | Thickness Gauge for High Loft materials |  Thickness Gauge for High Loft materials, with measurement Range up to 200 mm, is used to measure the thickness of high loft non - woven materials. Thickness is determined by examining the linear distance in which a moveable plane is displaced from a parallel surface by the specimen while under a specified pressure. Tests are carried out as per ASTM D 5736 Thickness Gauge for High Loft materials, with measurement Range up to 200 mm, is used to measure the thickness of high loft non - woven materials. Thickness is determined by examining the linear distance in which a moveable plane is displaced from a parallel surface by the specimen while under a specified pressure. Tests are carried out as per ASTM D 5736 |

| 62 | Liquid Nitrogen Plant |  Liquid Nitrogen Plant of capacity 20 LPD Liquid is used to separate the Nitrogen from environmental air and convert it into liquid form, having ≥99% purity, in a closed cylinder. System with Cryo -Refrigeretor from Cryomech (USA) has 100 L Storage capacity Liquid Nitrogen Plant of capacity 20 LPD Liquid is used to separate the Nitrogen from environmental air and convert it into liquid form, having ≥99% purity, in a closed cylinder. System with Cryo -Refrigeretor from Cryomech (USA) has 100 L Storage capacity |

| 63 | Portable 3D Scanner |  Portable 3D scanner based on blue light technology is perfect for capturing small objects with intricate curves and details such as molded parts, PCB ’s, components, etc. It possess 3D point accuracy upto 0 .05mm and volume capture zone of 2,000 cm³. Portable 3D scanner based on blue light technology is perfect for capturing small objects with intricate curves and details such as molded parts, PCB ’s, components, etc. It possess 3D point accuracy upto 0 .05mm and volume capture zone of 2,000 cm³. |

| 64 | Low Temperature Universal Testing Machine |  Low Temperature Universal Testing Machine is used for measuring tensile, tear, elongation & peel strength of various textile, polymeric and rubber materials as per ASTM, DIN & IS standards. UTM is equipped with load cells of 1, 10 & 50 KN and is capable to test the specimen in temperature rang of -50 0 C to +100 0C inside the environmental chamber (With liquid nitrogen dewar flask). Different grips available for the system are Heavy duty wedge grip, Medium -duty pneumatic grip, Pneumatic yarn grip and Variable angel peel strength grip . Low Temperature Universal Testing Machine is used for measuring tensile, tear, elongation & peel strength of various textile, polymeric and rubber materials as per ASTM, DIN & IS standards. UTM is equipped with load cells of 1, 10 & 50 KN and is capable to test the specimen in temperature rang of -50 0 C to +100 0C inside the environmental chamber (With liquid nitrogen dewar flask). Different grips available for the system are Heavy duty wedge grip, Medium -duty pneumatic grip, Pneumatic yarn grip and Variable angel peel strength grip . |

| 65 | Hydraulic Press |  Four column hydraulic press of 10 Ton capacity having stroke length of 250 - 300 mm is used for fabrication of polymer matrix composite laminates. Maximum working pressure of main cylinder is 150 kg /cm 2 and top and bottom plate can be heated up to 450° C . Four column hydraulic press of 10 Ton capacity having stroke length of 250 - 300 mm is used for fabrication of polymer matrix composite laminates. Maximum working pressure of main cylinder is 150 kg /cm 2 and top and bottom plate can be heated up to 450° C . |

| 66 | Impact Testing Machine |  Izod and Charpy impact testing machine ( Model AE - ICT -FC) is fully computerized system to reach impact speed 3 .46 m /sec. Machine has resolution of 0 .0001 J. Digital motorized Notch cutter (Model AE -MNC - D) has resolution of 0 .001 mm. At a time 5 samples notching can be done with thickness of 3 .5 mm each by cutting tool angled at 45° Izod and Charpy impact testing machine ( Model AE - ICT -FC) is fully computerized system to reach impact speed 3 .46 m /sec. Machine has resolution of 0 .0001 J. Digital motorized Notch cutter (Model AE -MNC - D) has resolution of 0 .001 mm. At a time 5 samples notching can be done with thickness of 3 .5 mm each by cutting tool angled at 45° |

| 67 | Haze and Transmittance Measurement System |  Dual -beam spectrophotometer (256 element diode array and high resolution, concave holographic grating) based system is used for measurement of haze and transmittance of optically transparent samples. Geometry is Tt/0º or Td /0º per ASTM 1164, CIE 15 :2018. and transmission Modes are Total, Regular and Haze. The system confirms to various standards viz. Colorimetric: CIE 15 :2018, ASTM E1164, DIN 5033 Teil 7 and JIS Z 8741 Condition E, G and Haze: ASTM D1003 Dual -beam spectrophotometer (256 element diode array and high resolution, concave holographic grating) based system is used for measurement of haze and transmittance of optically transparent samples. Geometry is Tt/0º or Td /0º per ASTM 1164, CIE 15 :2018. and transmission Modes are Total, Regular and Haze. The system confirms to various standards viz. Colorimetric: CIE 15 :2018, ASTM E1164, DIN 5033 Teil 7 and JIS Z 8741 Condition E, G and Haze: ASTM D1003 |

| 68 | Melt Flow Index Tester |  The MFI tester measures Melt Flow Index (MFI) of thermoplastic polymers as per ASTM and ISO standards under ambient as well as inert gas blanket. Knowledge of MFI, an inverse measure of the melt viscosity, of a polymer / polymer blend is vital for choosing the mode & conditions of its processing. The MFI tester measures Melt Flow Index (MFI) of thermoplastic polymers as per ASTM and ISO standards under ambient as well as inert gas blanket. Knowledge of MFI, an inverse measure of the melt viscosity, of a polymer / polymer blend is vital for choosing the mode & conditions of its processing. |

| 69 | HDT /Vicat Softening Point Instrument |  Microprocessor controlled instrument determines the Heat Distortion Temperature and Vicat softening temperature for thermoplastic polymers as per ASTM, DIN and ISO standards. Test specimens are heated using a circulating oil bath at temperature up to 300°C. Three independent working stations, each with its own linear LVDT transducer and its own PT100 sensor, are used to record the local temperature . Microprocessor controlled instrument determines the Heat Distortion Temperature and Vicat softening temperature for thermoplastic polymers as per ASTM, DIN and ISO standards. Test specimens are heated using a circulating oil bath at temperature up to 300°C. Three independent working stations, each with its own linear LVDT transducer and its own PT100 sensor, are used to record the local temperature . |

| 70 | Co-rotating Twin Screw Extruder |  Brabender make twin screw extruder is used for polymer processing viz. colouring, filling and reinforcement, homogenization, venting, mixing / dispersion, reactive extrusion, etc. Using this system, processing steps relevant to all thermoplastic materials of diverse molecular architecture can be accomplished and compounding can be carried out within well defined plastication time. Modular design of the screw and barrel helps in optimizing and tailoring the compound preparation. The system can be operated as Twin Screw Extruder ( L /D : 48, D : 25 mm) and Single Screw Extruder ( L /D : 25, D : 19 mm) at max. temperature of 450 C. System is equipped with Variable speed Strand Cutter (Pelletizer), Melt Pump with Spinneret Die, Gravimetric Feeder / Volumetric Feeder / Side Feeder / Liquid Dosing Pump & Vacuum Port and has complete modularity for feed swapping and feed port pluggin Brabender make twin screw extruder is used for polymer processing viz. colouring, filling and reinforcement, homogenization, venting, mixing / dispersion, reactive extrusion, etc. Using this system, processing steps relevant to all thermoplastic materials of diverse molecular architecture can be accomplished and compounding can be carried out within well defined plastication time. Modular design of the screw and barrel helps in optimizing and tailoring the compound preparation. The system can be operated as Twin Screw Extruder ( L /D : 48, D : 25 mm) and Single Screw Extruder ( L /D : 25, D : 19 mm) at max. temperature of 450 C. System is equipped with Variable speed Strand Cutter (Pelletizer), Melt Pump with Spinneret Die, Gravimetric Feeder / Volumetric Feeder / Side Feeder / Liquid Dosing Pump & Vacuum Port and has complete modularity for feed swapping and feed port pluggin |